Benefits of Zinga

- ZINGA is safe and easy to use. It is a one-pack zinc coating system that can be applied by spraying, by brush/roll or by immersion. ZINGA is also available in spray cans.

- ZINGA can be applied in a workshop, but it can also be applied on site ; metal structures do not have to be dismantled before treatment (this is necessary with hot-dip galvanising).

- You can use ZINGA to recoat existing hot-dip galvanising in order to renew the cathodic protection.

- It is not always necessary to grit-blast surfaces. ZINGA can be applied on mildly rusty surfaces after they have been degreased. Loose rust and rust dust have to be removed.

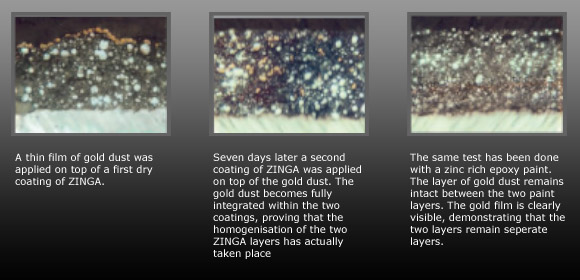

- Existing coatings of ZINGA can be covered with a new ZINGA layer : the old layer will reliquidise and fuse together to one single ZINGA layer (see pictures below).

- ZINGA is an excellent primer when a topcoat is required. A duplex system will multiply the sum of lifetimes of all layers with a factor of 1.5 to 2.5.

- ZINGA forms a barrier with a high resistance to mechanical abrasion mainly due to its flexibility (“squash-effect”).

- Adhesion tests have demonstrated that ZINGA has an excellent adhesion (mechanical and chemical) on steel. Even where it has been damaged by abrasion, ZINGA does not peel off , nor will it allow creeping rust.

ZINGA CAN BE EASILY RECHARGED

Each new coating of ZINGA blends perfectly with the previous one. Additional layers will all blend to one single ZINGA layer. Touching up can be done at any time at a minimal cost. An old ZINGA layer does not need to be removed before re-coating with ZINGA.